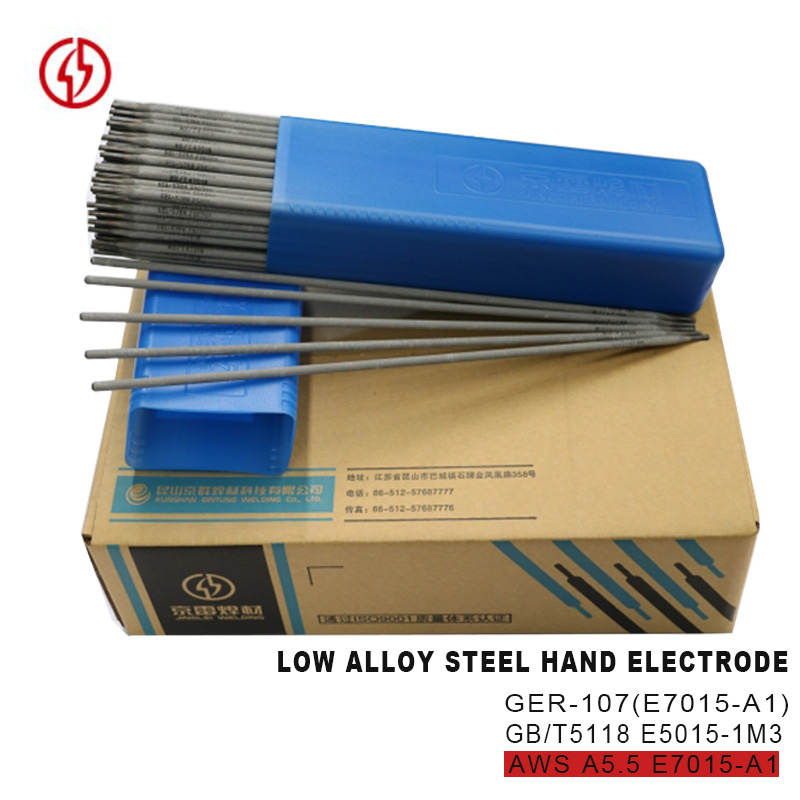

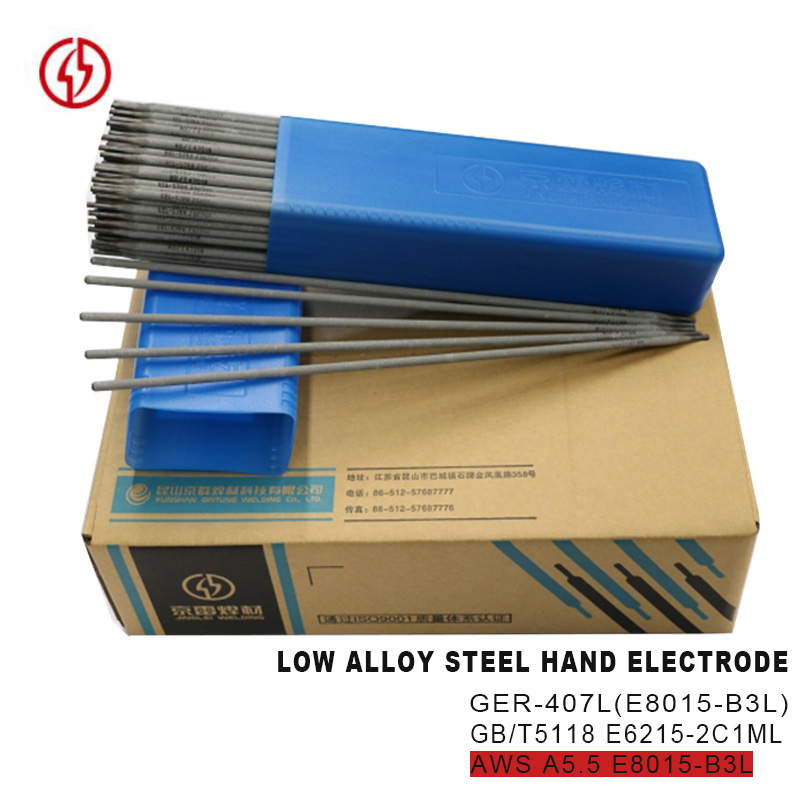

AWS E7015-A1 Low-alloy steels Afowoyi elekiturodu Welding ẹya ẹrọ

Ohun elo& Standard&Akiyesi:

E7015 Iru kekere alloy, irin ọwọ elekiturodu ni o dara fun alurinmorin ṣiṣẹ otutu ni isalẹ 510 ℃ igbomikana pipe, ooru paṣipaarọ ati awọn miiran nija, gẹgẹ bi awọn ASTM A204 ati A335-P1 paipu;

Awọn elekiturodu gbọdọ wa ni gbẹ ṣaaju ki o to lilo, pa a kukuru aaki, awọn lilo ti sẹhin siwaju alurinmorin ọna, yago fun awọn iṣẹlẹ ti porosity ni aaki; Kekere hydrogen yẹ ki o wa ni muduro jakejado alurinmorin ilana. Aṣayan elekiturodu irin kekere alloy, nigbagbogbo ni ibamu si akopọ kemikali ti irin, awọn ohun-ini ẹrọ, idena kiraki ati awọn ibeere miiran, ṣugbọn tun lati apẹrẹ ọna alurinmorin, awọn ipo iṣẹ, aapọn ati ohun elo alurinmorin ati awọn apakan miiran ti akiyesi okeerẹ. Ti o ba jẹ dandan, awọn idanwo iṣẹ alurinmorin yoo ṣee ṣe lati pinnu elekiturodu ati awọn igbese ilana pataki ni yoo mu.

Awọn ẹya ara ẹrọ

1. Low sodium hydrogen elekiturodu, fifi 0.5% Mo lati mu weld agbara ati ipata resistance;

2. Stable arc, kere asesejade, ti o dara lara, rọrun lati desagger, X-Ray išẹ jẹ o tayọ.

Gbogbo yan awọn ti o baamu elekiturodu ni ibamu si awọn agbara ti irin ite, ni akoko kanna tun nilo lati irin weldability, awọn orilede ti obi irin irinše, agbodo lati dahun awọn iwọn be, apẹrẹ, yara ati awọn okunfa ifọkansi wahala, gẹgẹ bi awọn okeerẹ. ero, awọn itutu iyara ti alurinmorin jẹ ju ńlá, ni kan ti o ga agbara, weld ita awọn ọja awọn iṣọrọ kiraki awọn ikolu ti ayidayida, igba le yan diẹ ninu awọn kere ju awọn agbara ti obi irin elekiturodu.

Ile-iṣẹ & Ile-iṣẹ

Ọja tiwqn ati darí-ini ifihan

KỌMPUTA kemikali

| ALOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T OFIN | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| Aws ofin | 0.12 | 0.90 | 0.60 | - | 0.40-0.65 | 0.03 | 0.030 |

| APEERE IYE | 0.07 | 0.75 | 0.35 | 0.035 | 0.55 | 0.014 | 0.012 |

Ohun-ini ẹrọ:

| ONÍNÌYÀN | AGBARA YIELD(MPa) | AGBARA Ifaagun (MPa) | ÌTẸ̀RẸ̀YÌN ℃xh | IMAPACT IYE J/℃ | ÌGBÀGBÀ(%) | |||||||||

| GB/T OFIN | 390 | 490 | 620*1 | - | 22 | |||||||||

| Aws ofin | 390 | 490 | 620*1 | - | 22 | |||||||||

| APEERE IYE | 477 | 570 | 620*1 | 150 / Deede otutu | 28 | |||||||||

Niyanju welding PARAMETER:

| DIAMETERS PIPICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0 * 400 | 5.0 * 400 | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

Awọn alaye Iṣakojọpọ:

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27 PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||

Awọn ọran Aṣoju

Iwe-ẹri

Ọja tiwqn ati darí-ini ifihan

KỌMPUTA kemikali

| ALOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T OFIN | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| Aws ofin | 0.12 | 0.90 | 0.60 | - | 0.40-0.65 | 0.03 | 0.030 |

| APEERE IYE | 0.07 | 0.75 | 0.35 | 0.035 | 0.55 | 0.014 | 0.012 |

Ohun-ini ẹrọ:

| ONÍNÌYÀN | AGBARA YIELD(MPa) | AGBARA Ifaagun (MPa) | ÌTẸ̀RẸ̀YÌN ℃xh | IMAPACT IYE J/℃ | ÌGBÀGBÀ(%) | |||||||||

| GB/T OFIN | 390 | 490 | 620*1 | - | 22 | |||||||||

| Aws ofin | 390 | 490 | 620*1 | - | 22 | |||||||||

| APEERE IYE | 477 | 570 | 620*1 | 150 / Deede otutu | 28 | |||||||||

Niyanju welding PARAMETER:

| DIAMETERS PIPICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0 * 400 | 5.0 * 400 | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

Awọn alaye Iṣakojọpọ:

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27 PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||