AWS E7018-A1 Low-alloy steels Irin lulú alurinmorin waya Awọn ẹya ẹrọ Welding

Ohun elo& Standard&Akiyesi:

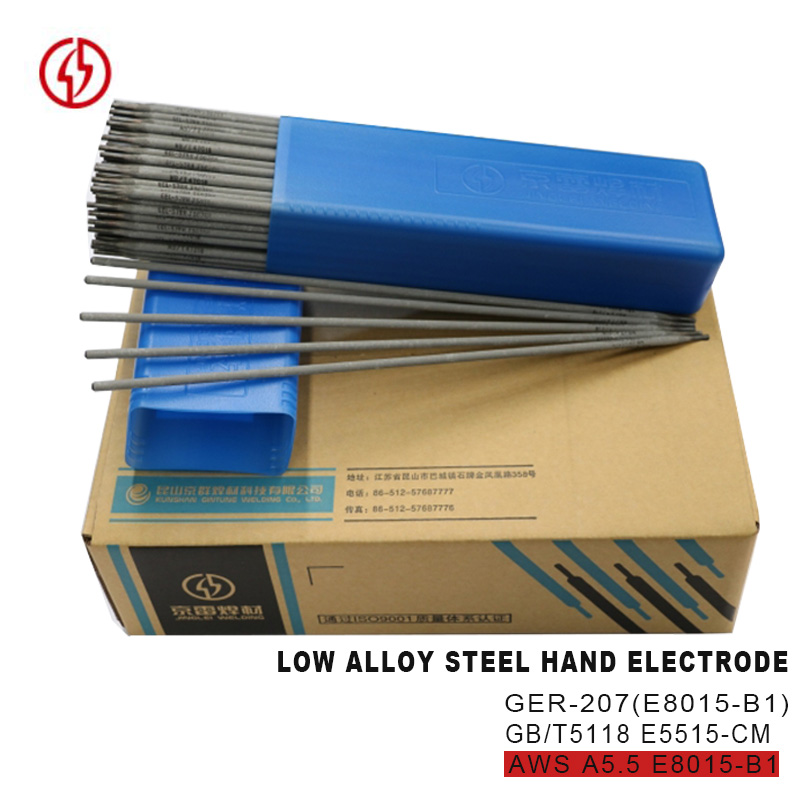

AWS E7018-A1 (R106Fe) elekiturodu ọwọ irin sooro ooru jẹ o dara fun paipu igbomikana alurinmorin, paipu alapapo alapapo ooru ati paipu nya si isalẹ 450 ℃ (bii 15MoG, T1, P1 irin) ati awọn iṣẹlẹ miiran. Bii ASTM A204 ati A335-P1 tubes; Awọn weldment yẹ ki o wa preheated si 90-110 ℃ ṣaaju ki o to alurinmorin, ati ki o bojuto awọn interlayer otutu. Tun le ṣee lo fun alurinmorin gbogboogbo kekere alloy irin ga agbara irin be. Ki o si yi ọwọ elekiturodu le ṣee lo fun ni kikun ipo alurinmorin. Gẹgẹbi awọn abuda ti ilana iṣelọpọ ti gaasi olomi iwọn otutu kekere, irin iwọn otutu kekere ni a lo ni awọn onipò oriṣiriṣi ni ibamu si awọn iwọn otutu iṣẹ oriṣiriṣi (-40 ℃, -70 ℃, -100 ℃, -194℃, -253℃ ), ati awọn ohun elo alurinmorin ti o baamu ti yan.

Awọn ẹya ara ẹrọ

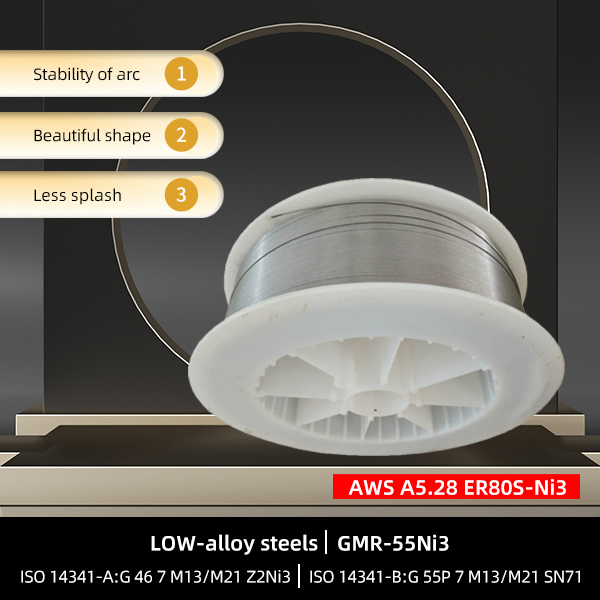

Iru elekiturodu ọwọ yii jẹ irin lulú kekere iru hydrogen iru elekiturodu, fifi irin lulú, ṣiṣe yo to gaju; 0.5% Mo ti wa ni afikun lati mu ilọsiwaju weld ati resistance resistance; Ati arc jẹ iduroṣinṣin, kere si splashing, lara, desagging jẹ rọrun, iṣẹ X-Ray dara.

Awọn eroja alloying ti o wọpọ ti pearlitic ooru sooro irin jẹ chromium, molybdenum, vanadium, niobium ati bẹbẹ lọ lati pade awọn ibeere iṣẹ oriṣiriṣi. Nitori iṣẹ apapọ ti awọn eroja alloy carbon ni irin, o rọrun lati ṣe agbekalẹ eto lile lakoko alurinmorin, ati pe iṣẹ alurinmorin ko dara. Nitorinaa, irin-sooro ooru pearlitic jẹ igbona ni gbogbogbo ṣaaju alurinmorin ati ki o tutu lẹhin alurinmorin.

Ile-iṣẹ & Ile-iṣẹ

Ọja tiwqn ati darí-ini ifihan

Ọja tiwqn ati darí-ini ifihan

KỌMPUTA kemikali

| ALOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T OFIN | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| Aws ofin | 0.12 | 0.90 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| APEERE IYE | 0.6 | 0.7 | 0.31 | 0.035 | 0.5 | 0.012 | 0.01 |

Ohun-ini ẹrọ:

| ONÍNÌYÀN | AGBARA YIELD(MPa) | AGBARA Ifaagun (MPa) | ÌTẸ̀RẸ̀YÌN ℃xh | IMAPACT IYE J/℃ | ÌGBÀGBÀ(%) | |||||||||

| GB/T OFIN | 390 | 490 | 620*1 | - | 22 | |||||||||

| Aws ofin | 390 | 490 | 620*1 | - | 22 | |||||||||

| APEERE IYE | 480 | 570 | 620*1 | 170 / Deede otutu | 26 | |||||||||

Niyanju welding PARAMETER:

| DIAMETERS PIPICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0 * 400 | 5.0 * 400 | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

Awọn alaye Iṣakojọpọ:

| ÌSÍPÍṢẸ́ | AGBO | PCS/1KG | ÌWÚN/1KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27 PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||

Awọn ọran Aṣoju

Iwe-ẹri

Ọja tiwqn ati darí-ini ifihan

KỌMPUTA kemikali

| ALOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T OFIN | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| Aws ofin | 0.12 | 0.90 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| APEERE IYE | 0.6 | 0.7 | 0.31 | 0.035 | 0.5 | 0.012 | 0.01 |

Ohun-ini ẹrọ:

| ONÍNÌYÀN | AGBARA YIELD(MPa) | AGBARA Ifaagun (MPa) | ÌTẸ̀RẸ̀YÌN ℃xh | IMAPACT IYE J/℃ | ÌGBÀGBÀ(%) | |||||||||

| GB/T OFIN | 390 | 490 | 620*1 | - | 22 | |||||||||

| Aws ofin | 390 | 490 | 620*1 | - | 22 | |||||||||

| APEERE IYE | 480 | 570 | 620*1 | 170 / Deede otutu | 26 | |||||||||

Niyanju welding PARAMETER:

| DIAMETERS PIPICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0 * 400 | 5.0 * 400 | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

Awọn alaye Iṣakojọpọ:

| ÌSÍPÍṢẸ́ | AGBO | PCS/1KG | ÌWÚN/1KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27 PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||