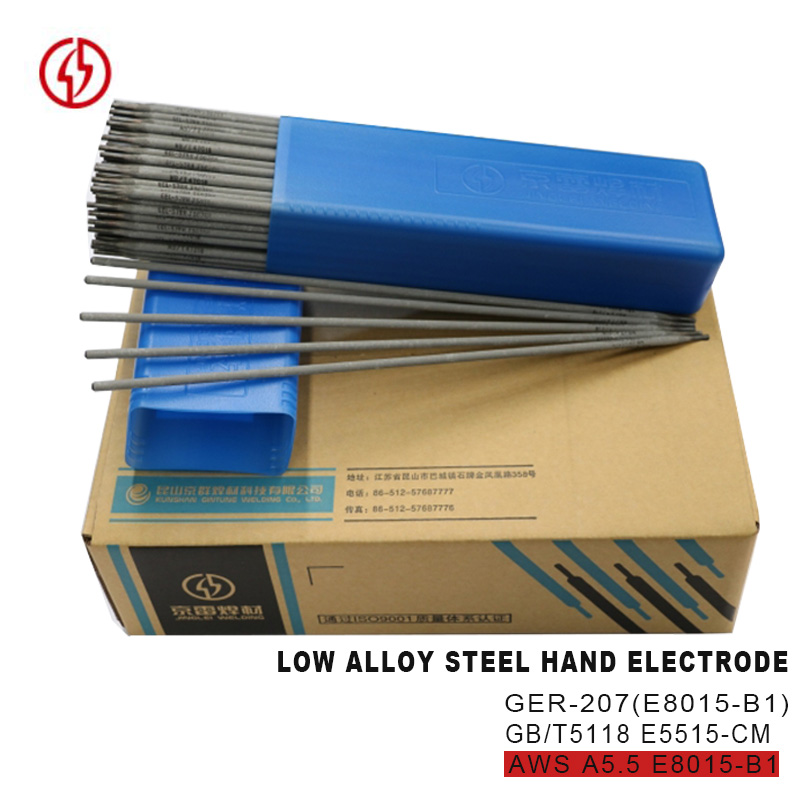

AWS E8015-B1 Low-alloy steels Afowoyi elekiturodu Welding nkan na

Ohun elo& Standard&Akiyesi:

GER-207 ooru sooro, irin ọwọ alurinmorin ọpá (R207) 0.5% Cr-0.5% Mo irin ọwọ alurinmorin ọpá ni o dara fun alurinmorin CrMo pearlite ooru sooro irin ati ki o ga otutu, ga titẹ opo, kemikali awọn apoti ati awọn miiran ti o baamu irin, gẹgẹ bi awọn 12CrMo tube awo, A335-P2 tube, A387Gr.2 awo. Awọn ipo alurinmorin: preheating ati ikanni (Layer) otutu: 160 ~ 190 ℃; 3. Itọju igbona: 690 ± 15 ℃x1h itọju ooru ni a ṣe ni ibamu si awọn ibeere boṣewa ti awọn ohun elo alurinmorin.

AWS E8015-B1 iru ẹrọ elekiturodu fun ooru sooro irin ni o dara fun alurinmorin CrMo pearlite ooru sooro irin (gẹgẹ bi awọn 12CrMo, ati be be lo) ati ki o ga otutu, ga titẹ opo, kemikali eiyan ati awọn miiran ti o baamu irin. Ṣaaju ki o to alurinmorin, elekiturodu gbọdọ wa ni ndin ni iwọn 350 ℃ fun 1h, ati lẹhinna lo pẹlu yan. Ṣaaju ki o to alurinmorin, awọn weldment gbọdọ wa ni ti mọtoto ti ipata, epo, omi ati awọn miiran impurities.

Awọn ẹya ara ẹrọ

AWS E8015-B1 (R207) iru ọwọ alurinmorin elekiturodu fun ooru sooro irin ni a kekere soda hydrogen iru ọwọ alurinmorin elekiturodu, idurosinsin aaki, kere asesejade, ti o dara lara, rorun desagging, X-Ray išẹ jẹ o tayọ. Electrode alurinmorin ọwọ jẹ lilo pupọ ni agbara ina, imọ-ẹrọ agbara, petrochemical ati awọn ile-iṣẹ miiran, ti o wọpọ julọ ti a lo Cr-Moh ati Mn-Mo iru ooru sooro irin ati Cr-Mo base multi-element alloy heat sooro irin. O tun jẹ dandan lati gba ọna ti preheating ṣaaju ipo alurinmorin ati alurinmorin deede fun alurinmorin irin sooro ooru. Ti o ba ti weldment ni lagbara, o yẹ ki o wa ni preheated bi kan gbogbo. Lẹhin alurinmorin, weldment yẹ ki o wa ni ipamọ loke iwọn otutu preheating fun awọn wakati pupọ, lẹhinna tutu laiyara.

Ile-iṣẹ & Ile-iṣẹ

Ọja tiwqn ati darí-ini ifihan

Ọja tiwqn ati darí-ini ifihan

KỌMPUTA kemikali

| ALOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T OFIN | 0.05-0.12 | 0.90 | 0.80 | 0.40-0.65 | 0.40-0.65 | 0.03 | 0.030 |

| Aws ofin | 0.05-0.12 | 0.90 | 0.80 | 0.40-0.65 | 0.40-0.65 | 0.03 | 0.030 |

| APEERE IYE | 0.078 | 0.72 | 0.35 | 0.56 | 0.53 | 0.016 | 0.01 |

Ohun-ini ẹrọ:

| ONÍNÌYÀN | AGBARA YIELD(MPa) | AGBARA Ifaagun (MPa) | ÌTẸ̀RẸ̀YÌN ℃xh | IMAPACT IYE J/℃ | ÌGBÀGBÀ(%) | |||||||||

| GB/T OFIN | 460 | 550 | 690*1 | - | 17 | |||||||||

| Aws ofin | 460 | 550 | 690*1 | - | 19 | |||||||||

| APEERE IYE | 490 | 590 | 690*1 | 90 / Deede otutu | 23 | |||||||||

Niyanju welding PARAMETER:

| DIAMETERS PIPICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0 * 400 | 5.0 * 400 | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

Awọn alaye Iṣakojọpọ:

| ÌSÍPÍṢẸ́ | AGBO | PCS/1KG | ÌWÚN/1KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27 PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||

Awọn ọran Aṣoju

Iwe-ẹri

Ọja tiwqn ati darí-ini ifihan

KỌMPUTA kemikali

| ALOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T OFIN | 0.05-0.12 | 0.90 | 0.80 | 0.40-0.65 | 0.40-0.65 | 0.03 | 0.030 |

| Aws ofin | 0.05-0.12 | 0.90 | 0.80 | 0.40-0.65 | 0.40-0.65 | 0.03 | 0.030 |

| APEERE IYE | 0.078 | 0.72 | 0.35 | 0.56 | 0.53 | 0.016 | 0.01 |

Ohun-ini ẹrọ:

| ONÍNÌYÀN | AGBARA YIELD(MPa) | AGBARA Ifaagun (MPa) | ÌTẸ̀RẸ̀YÌN ℃xh | IMAPACT IYE J/℃ | ÌGBÀGBÀ(%) | |||||||||

| GB/T OFIN | 460 | 550 | 690*1 | - | 17 | |||||||||

| Aws ofin | 460 | 550 | 690*1 | - | 19 | |||||||||

| APEERE IYE | 490 | 590 | 690*1 | 90 / Deede otutu | 23 | |||||||||

Niyanju welding PARAMETER:

| DIAMETERS PIPICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0 * 400 | 5.0 * 400 | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

Awọn alaye Iṣakojọpọ:

| ÌSÍPÍṢẸ́ | AGBO | PCS/1KG | ÌWÚN/1KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27 PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||