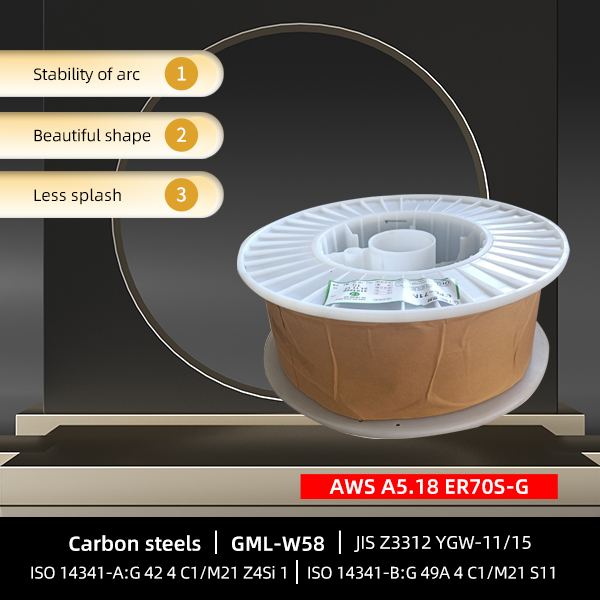

Awọn irin ti o ga julọ Erogba MIG ER70S-G isọpọ iṣelọpọ weld

Ohun elo

Dara fun ọkọ oju omi, afara, ikole ati awọn ohun elo alurinmorin excavation, tun lo ni alurinmorin awo ika ọwọ giga lọwọlọwọ, alurinmorin fillet ati alurinmorin agbelebu.

Boṣewa ti a pade: GB/T8110 G 49A4 C1/M21 S11 N, AWS A5.18 ER70S-G & A5.18M ER49S-G, ISO14341-A: G 42 4 C1/M21 Z4Si1, ISO 14341-B: G 49 4 C1 / M21 S11

JIS Z3312 YGW-11/15

Iyatọ

Idaabobo ayika ati ilera, ati pe o le yago fun ipa ikolu ti bàbà lori didara alurinmorin;

Ni afikun si awọn eroja alloying to dara gẹgẹbi Si ati Mn, awọn eroja Ti to ti wa ni afikun lati ṣe iduroṣinṣin arc ati ki o jẹ ki iyipada arc di mimọ; Awọn ojulumo iye asesejade ati ẹfin ti wa ni tun significantly dinku;

Ti ni awọn ipa ti ọkà isọdọtun ti awọn weld kọja, ki awọn toughness ti awọn weld kọja ti wa ni gidigidi dara si, ati awọn ti o tun le mu awọn oniwe-superior iṣẹ ni o tobi sisan alurinmorin.

Ṣe afihan awọn alaye

Imudara imudara si ni pataki

Ga lọwọlọwọ alurinmorin tun le mu awọn oniwe-superior iṣẹ

Nipa re

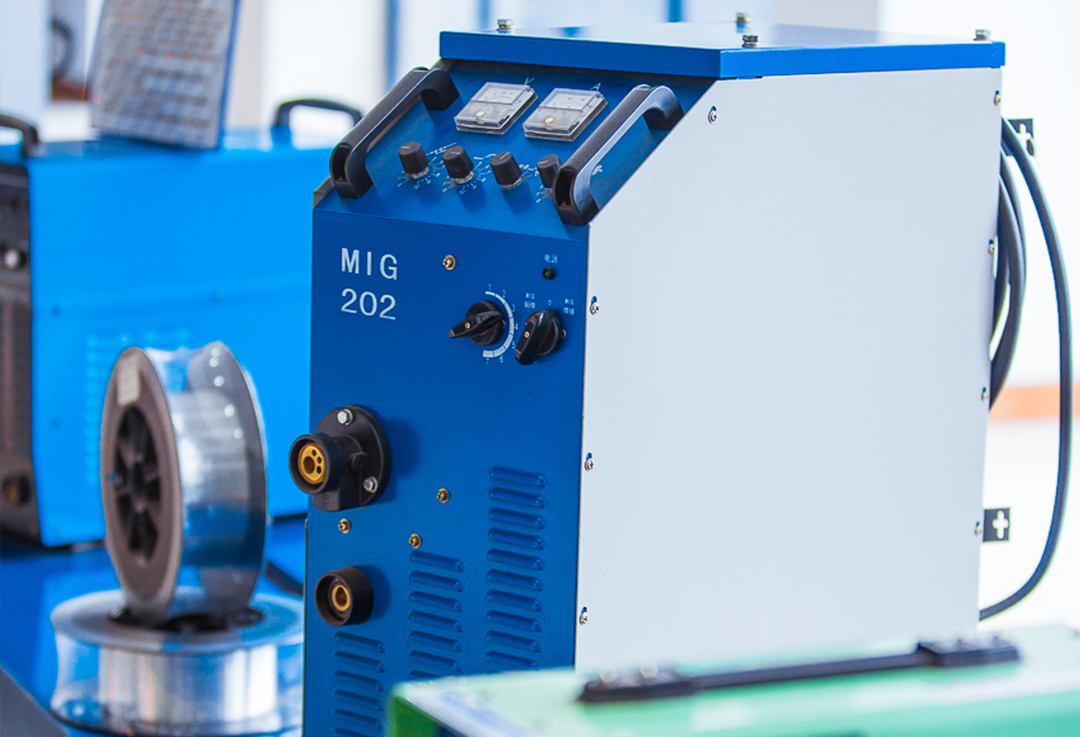

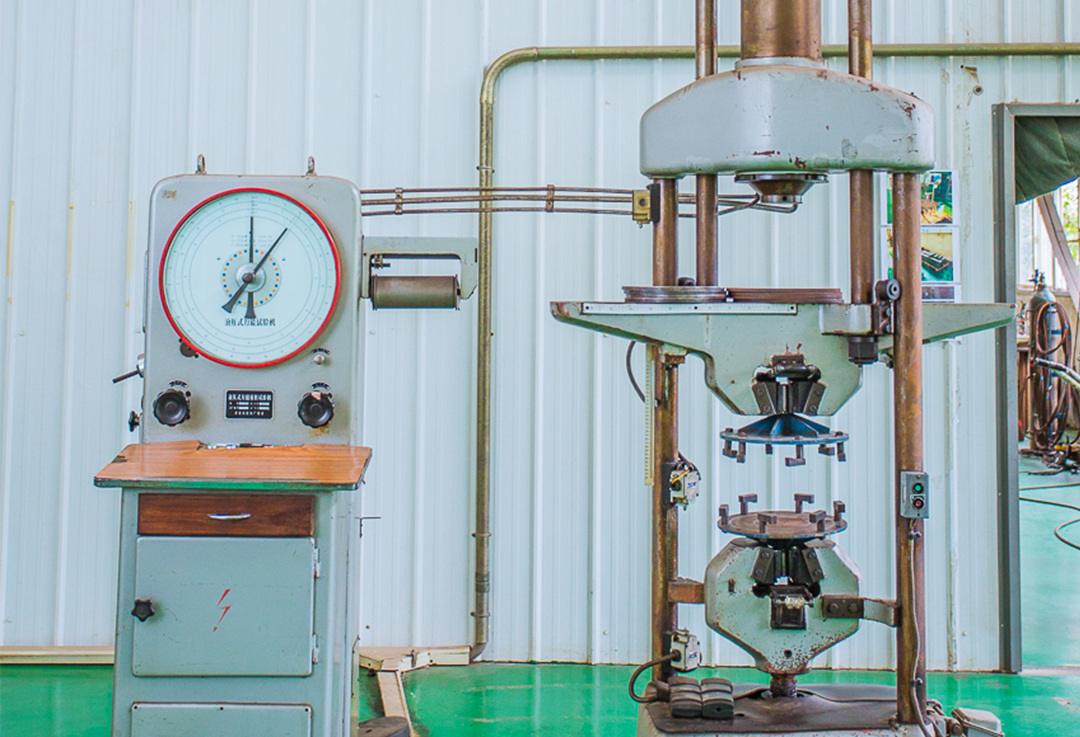

Factory fioor àpapọ

Ohun elo irú

Canada LNG Project

Ile-iṣọ imularada Hainan Huasheng phenol

Gangan factory ibon

KỌMPUTA kemikali

| ALOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Ti+Zr | P | S | Cu |

| GB/T OFIN | 0.02-0.151 | 0.40-1.90 | 0.55-1.10 | - | - | - | 0.02-0.30 | 0.300 | 0.030 | 0.50 |

| Aws ofin | - | - | - | - | - | - | - | - | - | - |

| APEERE IYE | 0.055 | 1.500 | 0.85 | 0.03 | 0.02 | 0.01 | 0.18 | 0.013 | 0.010 | 0.02 |

Ohun-ini ẹrọ:

| ONÍNÌYÀN | AGBARA YIELD(MPa) | AGBARA Ifaagun (MPa) | ÌTẸ̀RẸ̀YÌN ℃xh | IMAPACT IYE J/℃ | ÌGBÀGBÀ(%) | |||||

| GB/T OFIN | 390 | 490-670 | AW | 27/-40 | 18 | |||||

| Aws ofin | 400 | 490 | AW | - | 22 | |||||

| APEERE IYE | 500 | 590 | AW | 78/-40 | 28 | |||||

Niyanju welding PARAMETER:

| DIAMETERS PIPICATIONS(mm) | 1 | 1.2 | 1.6 | |||||

| ELECTRICITY (Amp) | H/W | 80-250 | 100-350 | 250-300 | ||||

| O/W | 70-120 | 80-150 | ||||||