Awọn irin alloy-kekere Afowoyi elekiturodu E8018-C1 awọn iṣelọpọ weld

KỌMPUTA kemikali

| ALOY(wt%) | C | Mn | Si | Ni | Cr | Mo | P | S |

| GB/T OFIN | 0.12 | 1.25 | 0.80 | 2.00-2.75 | - | - | 0.03 | 0.03 |

| Aws ofin | 0.12 | 1.25 | 0.80 | 2.00-2.75 | - | - | 0.03 | 0.03 |

| APEERE IYE | 0.055 | 0.85 | 0.32 | 2.2 | 0.023 | 0.11 | 0.007 | 0.006 |

Ohun-ini ẹrọ:

| ONÍNÌYÀN | AGBARA YIELD(MPa) | AGBARA Ifaagun (MPa) | IMAPACT IYE J/℃ | ÌGBÀGBÀ(%) | Itọju igbona °Cxh | |||||

| GB/T OFIN | 460 | 550 | 27/-60 | 17 | 605*1 | |||||

| Aws ofin | 460 | 550 | 27/-60 | 19 | 605*1 | |||||

| APEERE IYE | 475 | 580 | 95/-60 | 26 | 605*1 | |||||

Niyanju welding PARAMETER:

| DIAMETERS PIPICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0 * 400 | 5.0 * 400 | ||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||

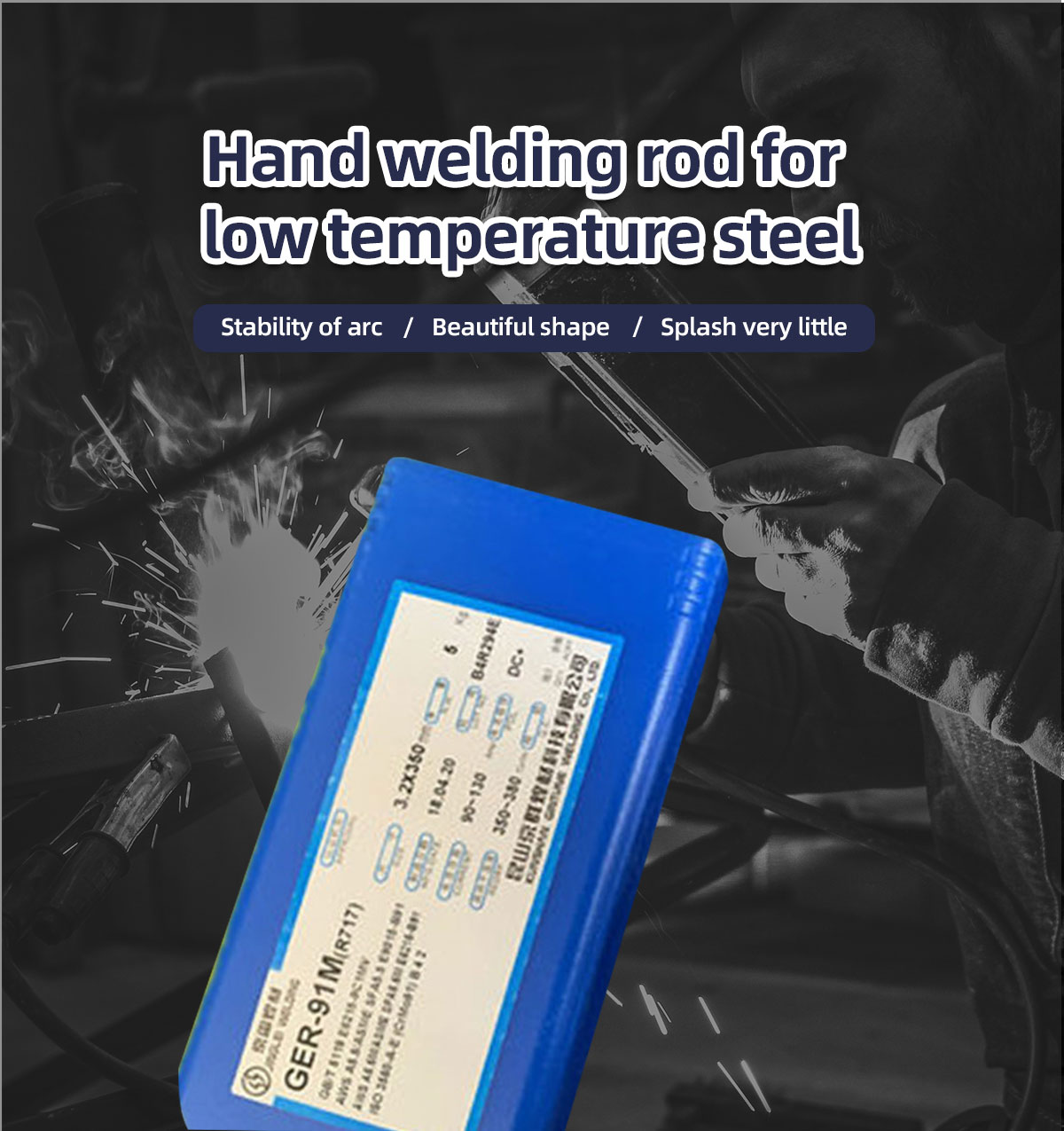

Irin lulú kekere hydrogen potasiomu iru ọwọ elekiturodu.

Nitori afikun ti irin lulú, yo ṣiṣe jẹ ti o ga, awọn ikolu toughness ti didà irin ni -60 ℃ ṣiṣẹ otutu jẹ o tayọ.

Idurosinsin aaki, kere asesejade, ti o dara lara, rorun slag yiyọ, X-Ray išẹ jẹ o tayọ.

igbomikana IwUlO

9,000 toonu ti kemikali

Sanmen iparun agbara ọgbin

KỌMPUTA kemikali

| ALOY(wt%) | C | Mn | Si | Ni | Cr | Mo | P | S |

| GB/T OFIN | 0.12 | 1.25 | 0.80 | 2.00-2.75 | - | - | 0.03 | 0.03 |

| Aws ofin | 0.12 | 1.25 | 0.80 | 2.00-2.75 | - | - | 0.03 | 0.03 |

| APEERE IYE | 0.055 | 0.85 | 0.32 | 2.2 | 0.023 | 0.11 | 0.007 | 0.006 |

Ohun-ini ẹrọ:

| ONÍNÌYÀN | AGBARA YIELD(MPa) | AGBARA Ifaagun (MPa) | IMAPACT IYE J/℃ | ÌGBÀGBÀ(%) | Itọju igbona °Cxh | |||||

| GB/T OFIN | 460 | 550 | 27/-60 | 17 | 605*1 | |||||

| Aws ofin | 460 | 550 | 27/-60 | 19 | 605*1 | |||||

| APEERE IYE | 475 | 580 | 95/-60 | 26 | 605*1 | |||||

Niyanju welding PARAMETER:

| DIAMETERS PIPICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0 * 400 | 5.0 * 400 | ||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||

Kọ ifiranṣẹ rẹ nibi ki o si fi si wa