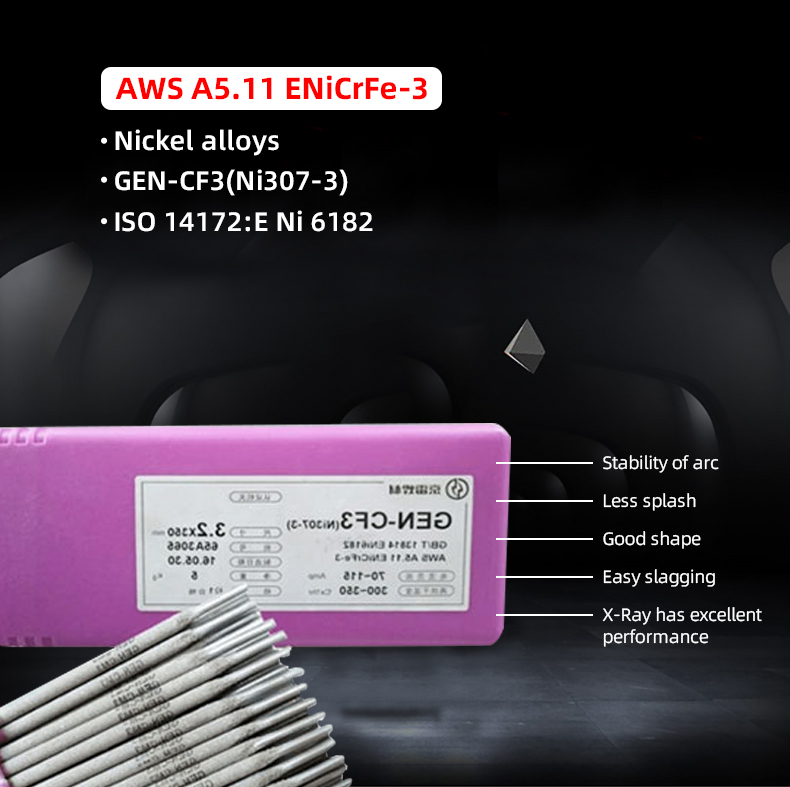

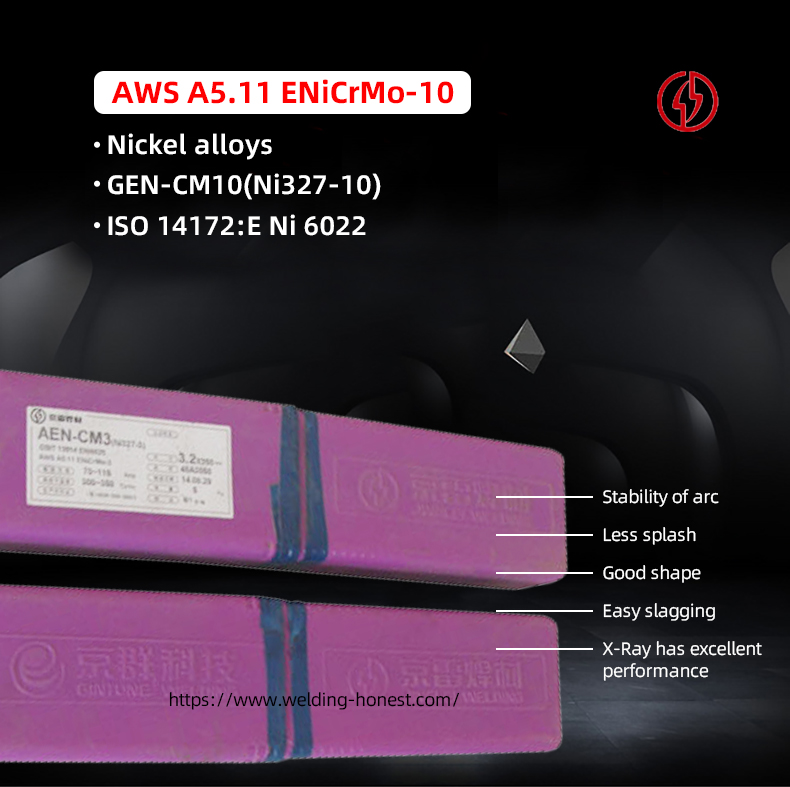

Nickel alloys Afowoyi elekiturodu ENiCrFe-3 Alurinmorin jointing

KỌMPUTA kemikali

| ALOY(wt%) | C | Mn | Si | Cr | Ni | Fe | Nb+Ta | P | S | |

| GB/T OFIN | 0.10 | 5.0-10.0 | 1.00 | 13.0-17.0 | ≥60 | 10.00 | 1.0-3.5 | 0.02 | 0.015 | |

| Aws ofin | 0.10 | 5.0-9.5 | 1.00 | 13.0-17.0 | ≥59 | 10.00 | 1.0-2.5 | 0.03 | 0.015 | |

| APEERE IYE | 0.046 | 7.6 | 0.45 | 15.7 | 15.7 | 3.56 | 1.76 | 0.005 | 0.004 | |

Ohun-ini ẹrọ:

| ONÍNÌYÀN | AGBARA YIELD(MPa) | AGBARA Ifaagun (MPa) | IMAPACT IYE J/℃ | ÌGBÀGBÀ(%) | ||||

| GB/T OFIN | 360 | 550 | - | 27 | ||||

| Aws ofin | - | 550 | - | 30 | ||||

| APEERE IYE | 410 | 650 | - | 40 | ||||

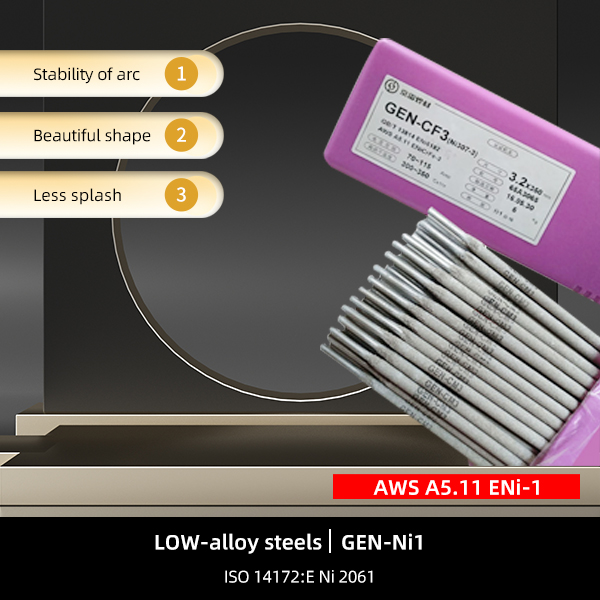

Niyanju welding PARAMETER:

| DIAMETERS PIPICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0 * 350 | ||||||||

| ELECTRICITY (Amp) | H/W | 69-95 | 70-115 | 95-145 | |||||||

| O/W | 55-80 | 65-110 | 80-130 | ||||||||

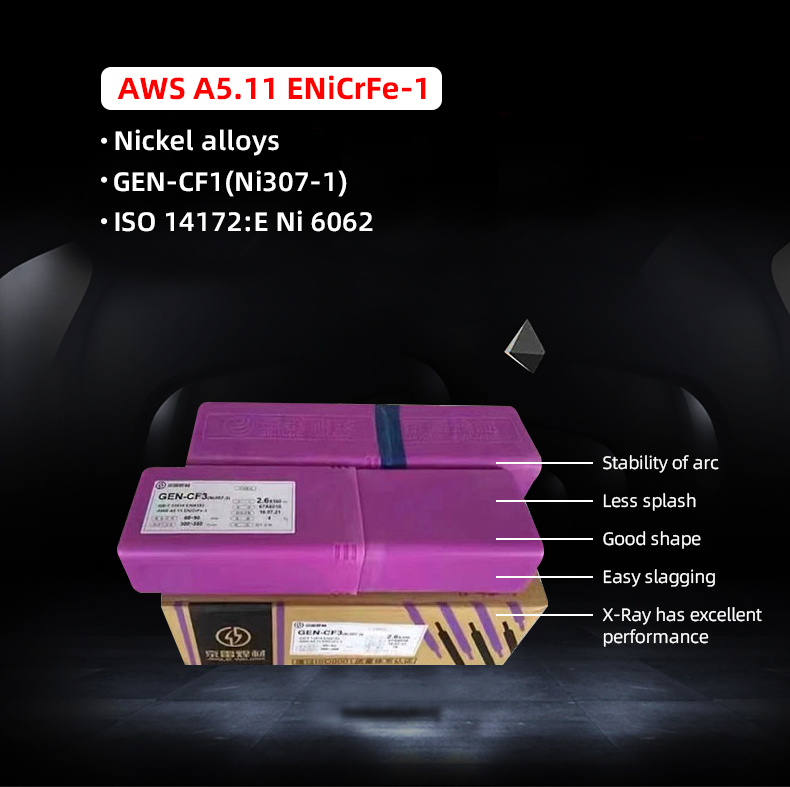

Elekiturodu ọwọ iru hydrogen kekere, akojọpọ ipin (ipin iwuwo) jẹ 65Ni-15Cr-8Fe-7.5Mn-2Nb+Ta, fun elekiturodu alloy nickel-chrome-iron.

Nitori awọn ga akoonu ti awọn alloy, o ni o ni ga ga otutu agbara ati ifoyina resistance ati ki o le orisirisi si si awọn iwọn otutu ibiti o lati kekere otutu si 480 ℃.

Idurosinsin aaki, lẹwa lara, kekere asesejade, rorun slag yiyọ, ti o dara porosity resistance, awọn darí-ini ti didà irin jẹ idurosinsin.

-

300,000-tọonu ti ilu okeere Isejade Lilefoofo ati Omi-itọju Ibi ipamọ (FPSO)

Harbin itanna mẹta enu CMT

-

Agbara Satẹlaiti Zhejiang 3× 60,000 m³ ojò ipamọ LPG

KỌMPUTA kemikali

| ALOY(wt%) | C | Mn | Si | Cr | Ni | Fe | Nb+Ta | P | S | |

| GB/T OFIN | 0.10 | 5.0-10.0 | 1.00 | 13.0-17.0 | ≥60 | 10.00 | 1.0-3.5 | 0.02 | 0.015 | |

| Aws ofin | 0.10 | 5.0-9.5 | 1.00 | 13.0-17.0 | ≥59 | 10.00 | 1.0-2.5 | 0.03 | 0.015 | |

| APEERE IYE | 0.046 | 7.6 | 0.45 | 15.7 | 15.7 | 3.56 | 1.76 | 0.005 | 0.004 | |

Ohun-ini ẹrọ:

| ONÍNÌYÀN | AGBARA YIELD(MPa) | AGBARA Ifaagun (MPa) | IMAPACT IYE J/℃ | ÌGBÀGBÀ(%) | ||||

| GB/T OFIN | 360 | 550 | - | 27 | ||||

| Aws ofin | - | 550 | - | 30 | ||||

| APEERE IYE | 410 | 650 | - | 40 | ||||

Niyanju welding PARAMETER:

| DIAMETERS PIPICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0 * 350 | ||||||||

| ELECTRICITY (Amp) | H/W | 69-95 | 70-115 | 95-145 | |||||||

| O/W | 55-80 | 65-110 | 80-130 | ||||||||

Kọ ifiranṣẹ rẹ nibi ki o si fi si wa