Irin alagbara, irin Afowoyi Electrode E312-17 ore ọkọ weld

WELDING TECHNOLOGY

Ma ṣe jẹ ki awọn ibeere

Tesiwaju lati lepa rẹ

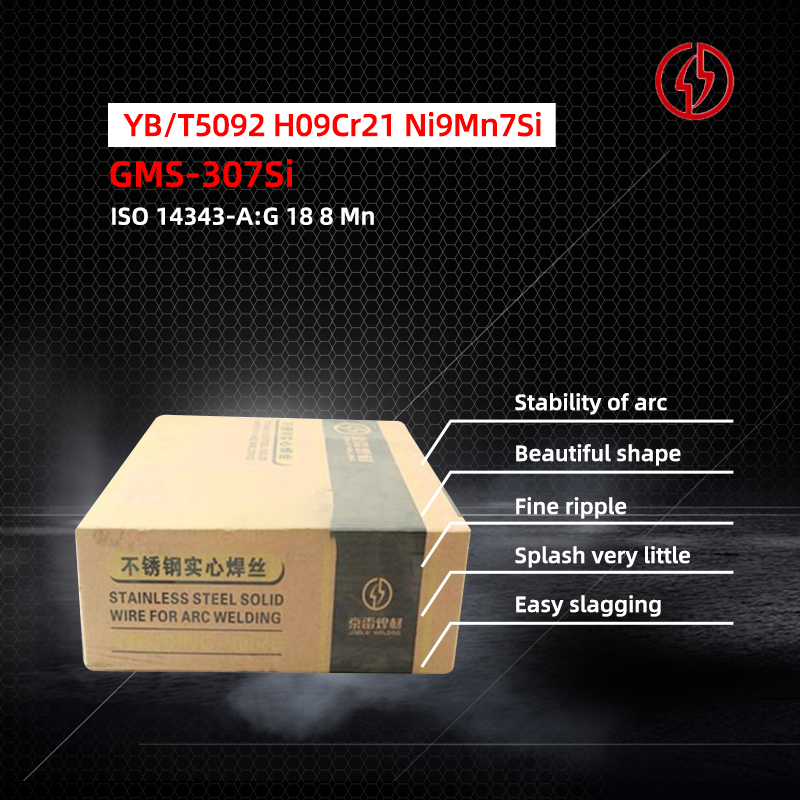

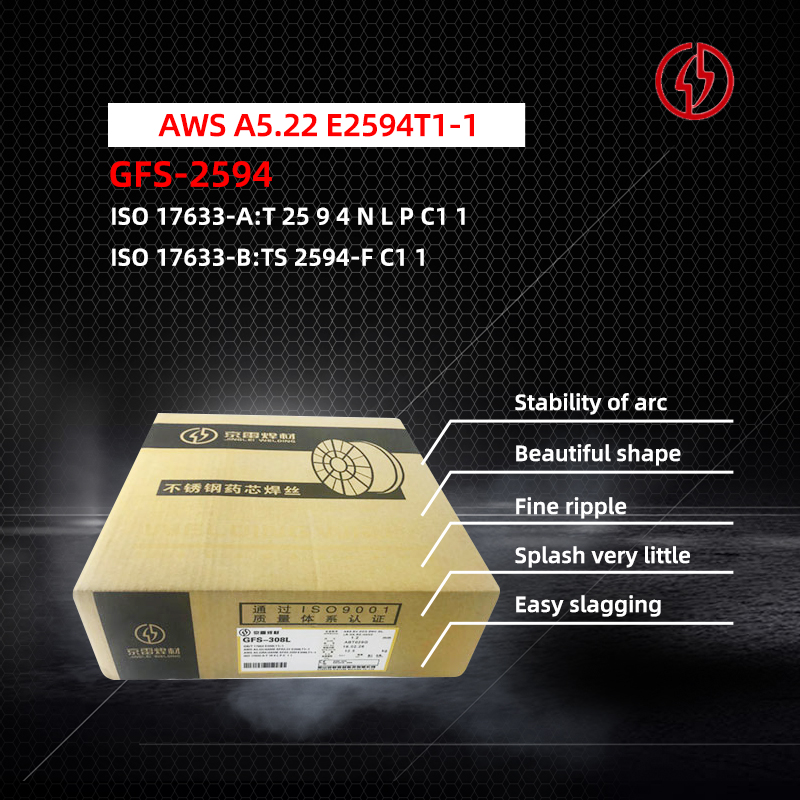

Arc aisedeede

Iṣatunṣe aibikita

Pupọ spatter

O dara fun gbogbo iru ohun elo irin lile ati lile

irin alloy eyiti o nira lati weld ati rọrun lati kiraki tabi ni porosity

Acid Iru meji-alakoso alagbara, irin ọwọ elekiturodu, oko ofurufu arc,

paati akọkọ jẹ 29% Cr-9% Ni, ti a mọ nigbagbogbo bi “elekiturodu gbogbo agbaye.

Ripple itanran

Iṣẹ alurinmorin to dara, aaki iduroṣinṣin, ṣiṣẹda lẹwa,

elege ripple, kekere asesejade, rorun slag yiyọ.

Awọn ti a bo ni o ni ti o dara ina resistance, ti o dara porosity resistance, ati idurosinsin darí-ini ti dapo irin

Rọrun slagging

Ọja Paramita

KỌMPUTA kemikali

| ALOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Omiiran |

| GB/T OFIN | 0.057 | 1.1 | 0.74 | 0.026 | 0.005 | 9.8 | 28.4 | 0.07 | 0.11 | - |

Ohun-ini ẹrọ:

| ONÍNÌYÀN | AGBARA YIELD(MPa) | AGBARA Ifaagun (MPa) | IMAPACT IYE J/℃ | Itọju ooru °C * h | ||||

| GB/T OFIN | 800 | 25 | - | - | ||||

Niyanju welding PARAMETER:

| DIAMETERS PIPICATIONS(mm) | 2.0 * 250 | 2.6*300 | 3.2*350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Factory support

Ọja naa dara fun a

jakejado ibiti o ti ohun elo

WELDING TECHNOLOGY

-

2.3 milionu awọn agba ti

SBM Fast4ward FPSO

-

GDS-2209 / GXS-E330

tube surfacing ojula

Hainan Huasheng

ẹṣọ imularada phenol

KỌMPUTA kemikali

| ALOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Omiiran |

| GB/T OFIN | 0.057 | 1.1 | 0.74 | 0.026 | 0.005 | 9.8 | 28.4 | 0.07 | 0.11 | - |

Ohun-ini ẹrọ:

| ONÍNÌYÀN | AGBARA YIELD(MPa) | AGBARA Ifaagun (MPa) | IMAPACT IYE J/℃ | Itọju ooru °C * h | ||||

| GB/T OFIN | 800 | 25 | - | - | ||||

Niyanju welding PARAMETER:

| DIAMETERS PIPICATIONS(mm) | 2.0 * 250 | 2.6*300 | 3.2*350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||