AWS A5.13 ENiCrFe-1 Nickel alloys Afowoyi elekiturodu Welding awọn ẹya ẹrọ

Ohun elo & Standard

ELECTRODE SURFACING COOBALT yii le ṣee lo fun ILA SLEEVE OF SEEVE SPEEVE, GEGE TI AWỌN ỌJỌ KẸMIKICAL FIBER Equipment, SAWTOOTH, SCREW PUSH ROD, iwọn otutu giga ati valve giga ati fifa titẹ giga ETC. Ibanujẹ dada ti workpiece yẹ ki o kere ju Ra12.5μm, ati ipata dada, epo ati idoti miiran yẹ ki o yọkuro muna. Matrix ko yẹ ki o ni awọn dojuijako, awọn pores, iyanrin ati awọn abawọn miiran, ati awọn egbegbe ati awọn igun yẹ ki o wa ni yika. Ṣaaju ki o to dada, awọn iwọn otutu oriṣiriṣi yẹ ki o yan ni ibamu si ohun elo sobusitireti fun preheating. Nigbati awọn ohun elo matrix jẹ pearlitic ooru-sooro, irin tabi martensitic alagbara, irin ati awọn ohun elo miiran pẹlu ko dara alurinmorin išẹ, awọn austenitic alagbara, irin surfacing Layer yẹ ki o wa ni welded lori awọn matrix dada, ati ki o si koluboti-orisun alloy yẹ ki o wa surfacing lẹhin dan processing lati. mu awọn kiraki resistance ki o si yago dojuijako. Boya AC tabi DC arc alurinmorin ipese agbara le ṣee lo fun D802 ati D812 amọna. Ipese agbara alurinmorin DC ni a gbaniyanju.

Awọn ẹya ara ẹrọ

GEH-SL12 titanium kalisiomu ti a bo koluboti-mimọ surfacing elekiturodu. Cobalt-cr-tungsten alloy ti lo bi okun waya mojuto. Dc asopọ yiyipada ti wa ni niyanju. Irin Surfacing le ṣetọju resistance yiya ti o dara ati resistance ipata ni 650 ℃. Ṣaaju ki o to alurinmorin, o gbọdọ wa ni ndin ni 300-350 ℃ fun 1 wakati; Layer lile lori oju irin ipilẹ yẹ ki o yọkuro lati yago fun awọn dojuijako ati brittleness. Ni ibamu si awọn iwọn ti awọn mimọ irin workpiece ati awọn iru ti mimọ irin, o gbọdọ wa ni preheated ni 300-600 ℃, ati kekere lọwọlọwọ arc alurinmorin jẹ yẹ.

Ile-iṣẹ & Ile-iṣẹ

Ọja tiwqn ati darí-ini ifihan

KỌMPUTA kemikali

| ALOY(wt%) | C | Mn | Si | Cr | Ni | P | Fe | Nb+Ta | S |

| GB/T OFIN | 0.08 | 3.5 | 0.80 | 13.0-17.0 | ≥62 | 0.02 | 11.0 | 0.5-4.0 | 0.015 |

| Aws ofin | 0.08 | 3.5 | 0.75 | 13.0-17.0 | ≥ | 0.03 | 11.0 | 1.5-4.0 | 0.015 |

| APEERE IYE | 0.048 | 2.97 | 0.34 | 15.6 | 69.6 | 0.005 | 8.94 | 2.65 | 0.007 |

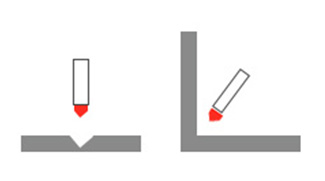

Niyanju welding PARAMETER:

| DIAMETERS PIPICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0 * 350 | |||||

| ELECTRICITY (Amp) | Alapin / petele alurinmorin | 69-95 | 70-115 | 95-145 | ||||

| inaro / oke alurinmorin | 55-80 | 65-110 | 80-130 | |||||

ÀWỌN ỌJỌ́ ÀGBÁRA

Awọn iwe-ẹri

Ọja tiwqn ati darí-ini ifihan

KỌMPUTA kemikali

| ALOY(wt%) | C | Mn | Si | Cr | Ni | P | Fe | Nb+Ta | S |

| GB/T OFIN | 0.08 | 3.5 | 0.80 | 13.0-17.0 | ≥62 | 0.02 | 11.0 | 0.5-4.0 | 0.015 |

| Aws ofin | 0.08 | 3.5 | 0.75 | 13.0-17.0 | ≥ | 0.03 | 11.0 | 1.5-4.0 | 0.015 |

| APEERE IYE | 0.048 | 2.97 | 0.34 | 15.6 | 69.6 | 0.005 | 8.94 | 2.65 | 0.007 |

Niyanju welding PARAMETER:

| DIAMETERS PIPICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0 * 350 | |||||

| ELECTRICITY (Amp) | Alapin / petele alurinmorin | 69-95 | 70-115 | 95-145 | ||||

| inaro / oke alurinmorin | 55-80 | 65-110 | 80-130 | |||||